December 2022 – June 2023

- New Skills Learned:

- Academic Technical Writing

- Thermoelectric Cooling

- Skills Reinforced:

- Mechanical Design

- FDM 3D Printing

- Machining

- Collaboration

I was approached by a CWRU graduate student about helping him design an enclosure to measure the reaction of cells to specific wavelengths of light. At first, he offered to pay for my CAD services but I decided to join his research team instead. My involvement in the research increased along with the scope of the project, and I ended up co-authoring the final research paper.

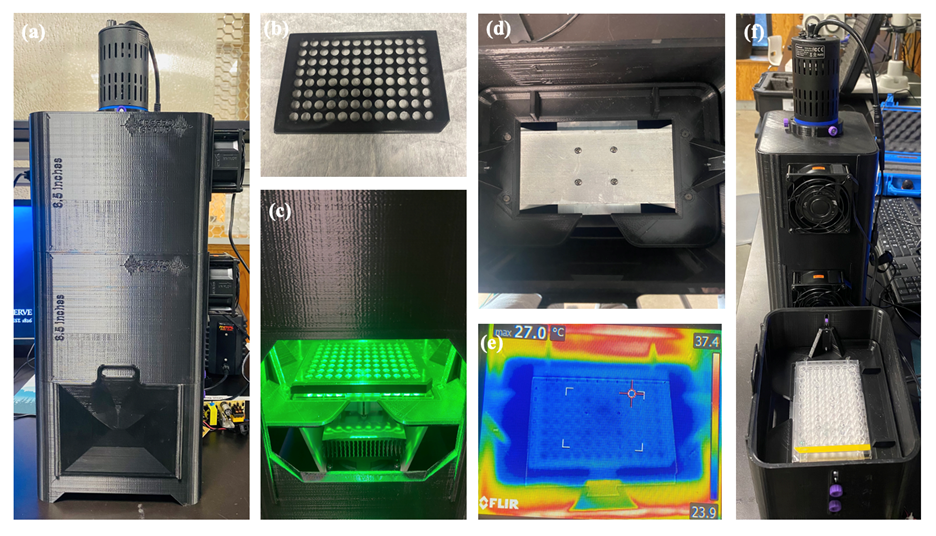

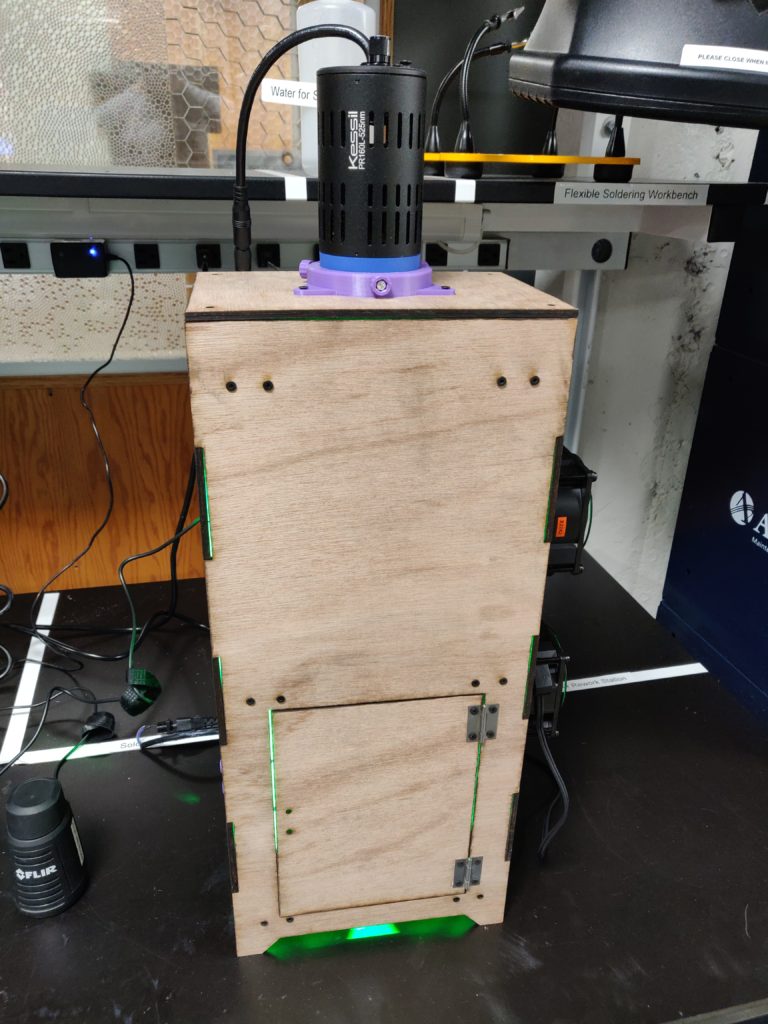

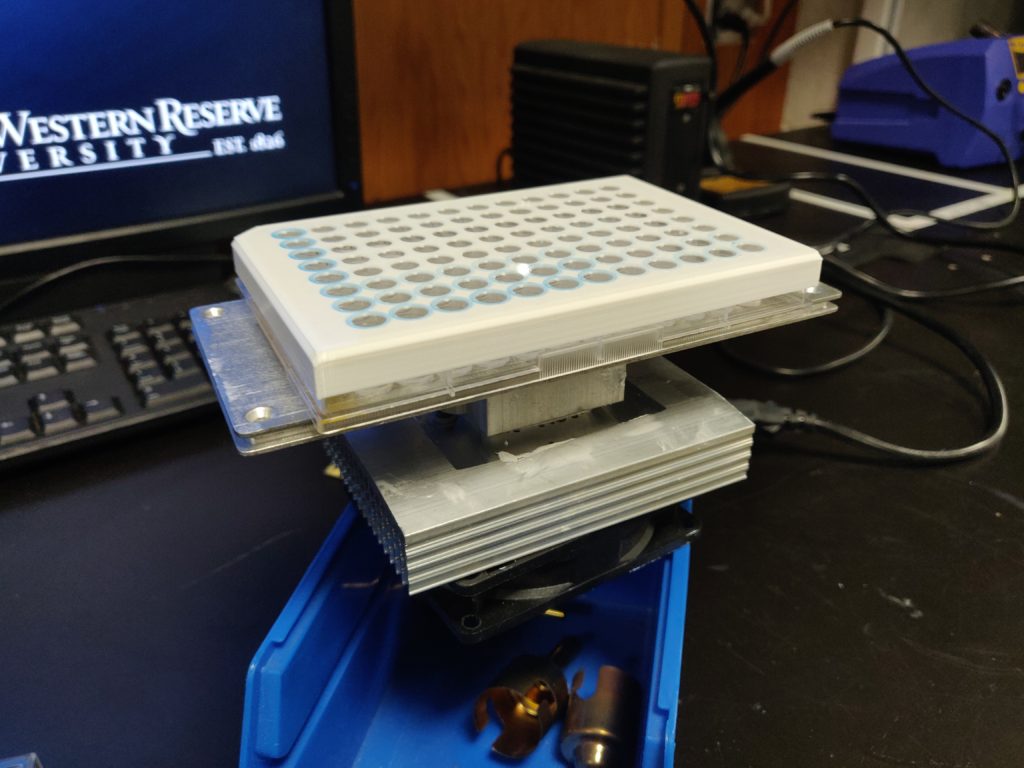

The setup consists of a modular enclosure that holds a specific light exactly 15 inches above a well plate full of cell samples. Fans and vents on the side of the unit ensure the internal air remains at ambient temperature. A thermoelectric cooling system recycled from a mini beverage cooler also actively cools the well plate, as there were some concerns that radiation from the light could raise their temperature.

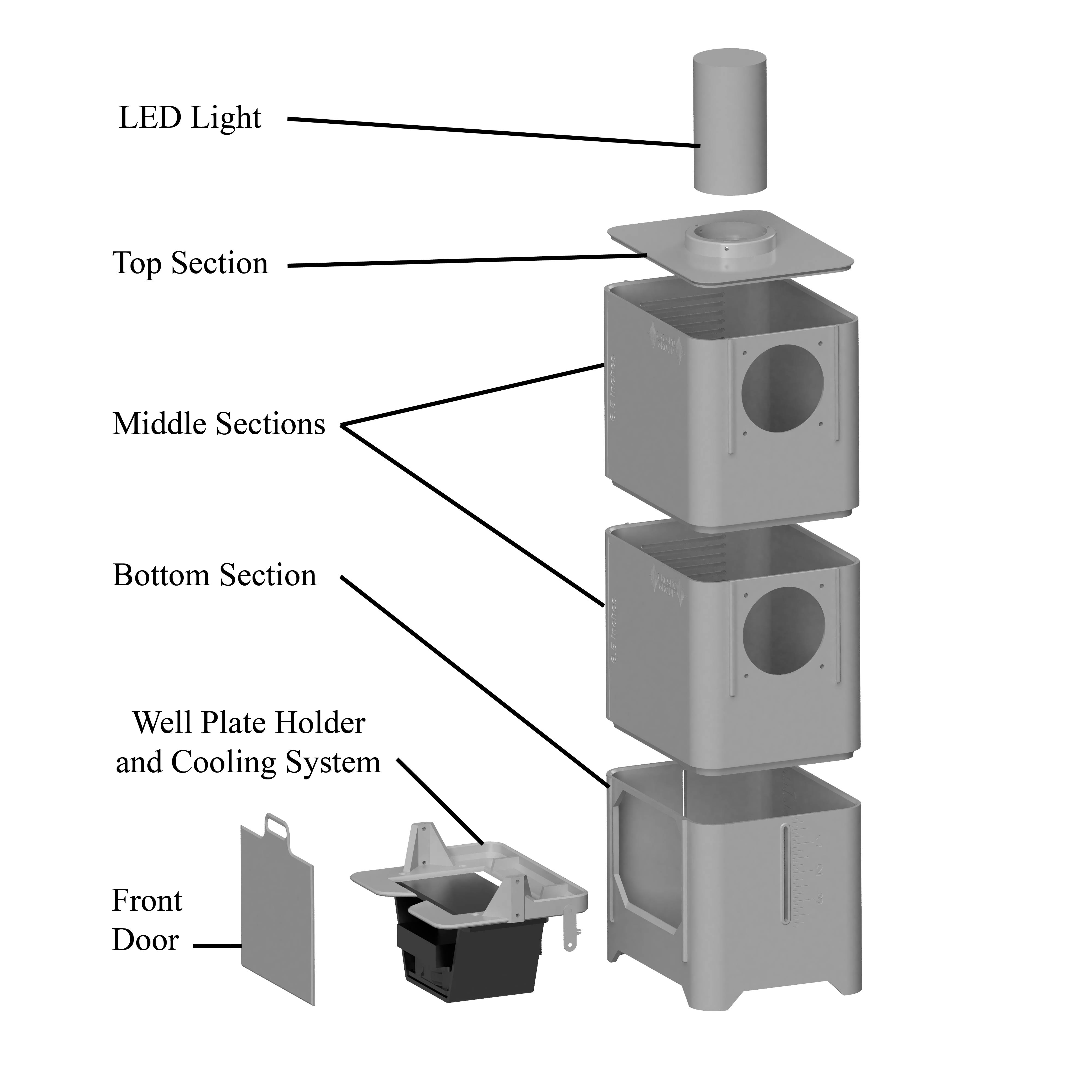

The first prototype was lasercut out of plywood, and exhibited some warping and light leakage. A second version was designed to be entirely 3D printed in modular sections. The modular design also improved ease of maintenance and storage.

During the initial design phase, we thought that the cooling system needed a closed loop control system. After some initial tests, however, we found simply running the cooling system constantly kept the cells at a suitable temperature.

The final paper, “Low-cost, 3D printed irradiation system for in vitro photodynamic therapy experiments”, was published in Photochemistry and Photobiology on November 6, 2023. You can read it online for free here!